Top Warnings You Need Immediate strapping machine service

Wiki Article

The Value of Regular Strapping Machine Service for Smooth and Reliable Product Packaging Processes

Regular strapping machine service plays an important duty in making certain reliable packaging procedures. Neglecting maintenance can result in unexpected malfunctions and decreased performance. By proactively dealing with possible concerns, organizations can enhance both machine performance and item high quality. Recognizing the value of normal service is basic for keeping operational efficiency. Lots of firms overlook this vital aspect. What variables should be considered to develop an efficient upkeep method?Recognizing Strapping Machines and Their Role in Packaging

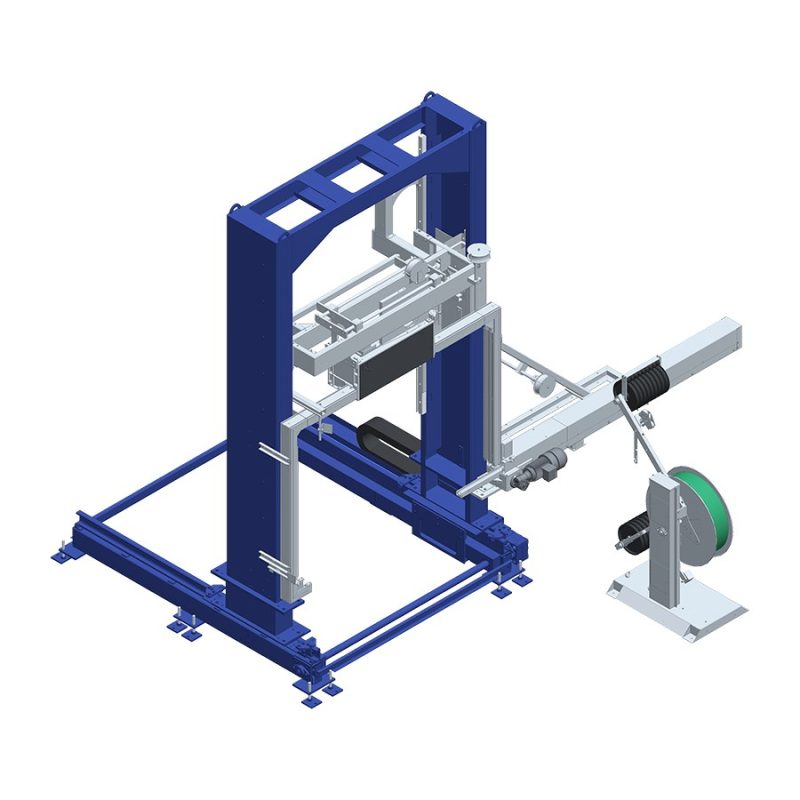

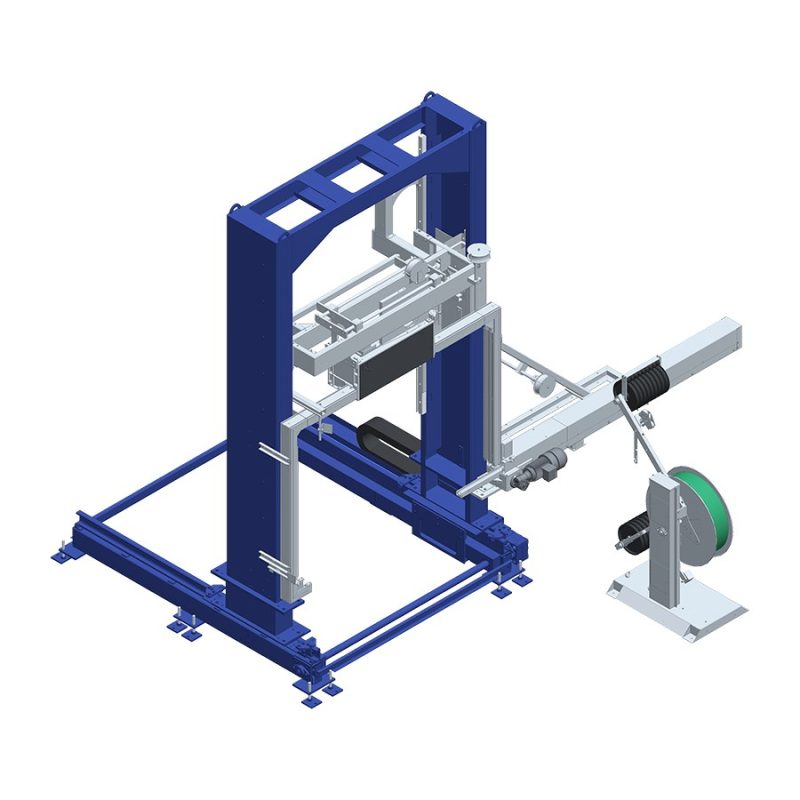

Strapping machines might seem like straightforward devices, they play a vital role in the product packaging sector by making sure the secure packing of items. These machines use plastic or steel straps around bundles, supplying stability throughout transportation and storage. By producing limited, dependable seals, strapping machines aid avoid damage and preserve item integrity. Their effectiveness adds to quicker packaging procedures, allowing organizations to fulfill raising need without compromising high quality. Furthermore, strapping machines can be integrated into automated systems, boosting operations and decreasing labor prices. The convenience of these machines makes them appropriate for numerous industries, from manufacturing to distribution, making certain that items continue to be intact throughout the supply chain. Inevitably, strapping machines are crucial to successful product packaging procedures.Usual Problems Emerging From Absence of Maintenance

When strapping machines are not properly preserved, several common problems can emerge that hinder their efficiency and reliability. Frequent breakdowns can occur because of damaged elements, bring about pricey downtimes and interrupted production schedules. Furthermore, incorrect tensioning might lead to weak seals, jeopardizing bundle honesty. Dust and debris buildup can hinder machine sensors and relocating components, triggering irregular operation and increased wear. Overlooked lubrication can lead to friction and getting too hot, further harmful inner mechanisms. Operators might likewise face obstacles when adjusting setups on badly kept machines, resulting in irregular product packaging results - strapping machine service. Overall, a lack of upkeep can significantly affect the performance and effectiveness of strapping machines, eventually impacting the entire product packaging processAdvantages of Normal Strapping Machine Service

Regular strapping machine service supplies significant advantages that add to operational success. By guaranteeing enhanced tools longevity and boosted operational performance, businesses can decrease the probability of unexpected breakdowns. Inevitably, this aggressive approach lowers downtime dangers, promoting an extra dependable production setting.Enhanced Equipment Durability

Maintaining a strapping machine via regular service substantially adds to its general long life. Routine evaluations and maintenance assistance recognize damage before they escalate right into considerable problems, thereby lengthening the life of vital elements. By resolving small faults promptly, drivers can avoid costly repair services and considerable downtime that can develop from overlook. Furthermore, regular servicing guarantees that all mechanical components function properly, decreasing the danger of machine failing during procedures. This positive strategy not just improves the strapping machine's sturdiness yet additionally cultivates a much safer working environment. Inevitably, spending in routine service converts to a more dependable machine that constantly fulfills production needs, protecting the stability of the product packaging process for years ahead.Improved Functional Performance

Routine service of strapping machines greatly improves functional effectiveness by guaranteeing that all elements operate at their best. Routine upkeep minimizes the danger of mechanical failings, enabling trustworthy and regular performance. Well-kept machines operate at optimal speeds, taking full advantage of throughput and lowering the time required for packaging processes. This performance not only assists satisfy manufacturing targets however additionally adds to a smoother workflow, as operators can depend on the tools without interruptions. In addition, routine maintenance determines prospective concerns early, allowing for rehabilitative actions to be taken before they escalate. As a result, companies experience structured procedures, which can bring about raised performance and enhanced overall efficiency in packaging jobs. Regular service is important for maintaining an efficient packaging setting.Decreased Downtime Dangers

Efficient service timetables for strapping machines significantly lower the threats of downtime connected with unforeseen mechanical failures. Regular maintenance checks aid recognize prospective concerns before they rise, guaranteeing that machines run efficiently and accurately. By resolving damage, lubrication needs, and electrical parts proactively, businesses can stay clear of costly interruptions in their packaging procedures. Furthermore, arranged servicing boosts the life expectancy of strapping machines, decreasing the frequency of substitutes and connected expenses. The decrease in unplanned downtime not only improves performance yet likewise improves staff member spirits, as employees can rely upon machinery that works flawlessly. Ultimately, devoting to routine service develops a durable operation, securing against disruptions and allowing business to satisfy manufacturing targets constantly.Key Components to Display Throughout Routine Service

While performing routine service on a strapping machine, it is essential to check several essential components to secure peak efficiency and long life. The tensioning system ought to be inspected for correct procedure, guaranteeing that straps are securely tightened without triggering damages. The securing system has to be examined for deterioration, as any type of breakdown can jeopardize the stability of the packaging. Additionally, the feed system calls for focus to guarantee smooth and constant strap shipment. It is likewise necessary to take try this out a look at electric links, as loosened or damaged circuitry can lead to operational failings. Lubrication degrees ought view it now to be examined to avoid friction-related problems, advertising effective machine feature. Routinely keeping track of these parts will certainly contribute significantly to the machine's overall dependability.Creating an Upkeep Arrange

A well-designed upkeep routine plays an essential function in guaranteeing the perfect operation of a strapping machine. It should consist of routine evaluations, cleansing, and component replacements based on the supplier's recommendations. Establishing a regularity for these tasks-- such as once a week, regular monthly, or quarterly-- can aid preemptively address possible problems. Additionally, recording each maintenance task improves liability and enables tracking the machine's performance in time. Operators needs to also take into consideration the production volume and certain functional demands when customizing the schedule. By prioritizing regular service, organizations can reduce downtime, extend the machine's life-span, and preserve constant packaging quality. Eventually, a thorough maintenance timetable is necessary for maximizing strapping machine capability and dependability in product packaging processes.Choosing the Right Service Provider

Just how can one ensure the selection of an ideal service providerfor strapping machine upkeep? It is crucial to research study potential companies extensively. Evaluating their experience, market reputation, and expertise in strapping machine technologies can provide useful understandings. Additionally, customer reviews and reviews frequently disclose the top quality of service and integrity.Next off, take into consideration the company's accreditation and training programs, which suggest their dedication to keeping high standards. It is likewise crucial to ask about their reaction times for service phone calls and the schedule of extra parts.

Finally, acquiring multiple quotes allows for a contrast of rates and service plans, ensuring an educated choice. Eventually, the right company will improve effectiveness and lower downtime in product packaging procedures.

The Long-Term Effect of Consistent Machine Treatment

Consistent machine treatment considerably influences the longevity and performance of strapping machines, as normal maintenance aids determine potential concerns before they intensify. By executing a structured service timetable, organizations can lessen unforeseen downtimes and costly fixings. This positive approach not only guarantees peak working yet also boosts the high quality of packaging, bring about improved consumer fulfillment. With time, well-kept machines exhibit far better efficiency, causing minimized functional prices and increased efficiency. In addition, a society of regular care fosters worker confidence in devices integrity, advertising a smoother operations. Inevitably, the long-term influence of regular machine treatment equates right into considerable financial savings and an affordable edge in the packaging market, making it an important method for companies seeking lasting growth.

Often Asked Questions

How Commonly Should I Change Strapping Machine Parts?

Strapping machine parts ought to be replaced every 1,000 to 2,000 hours of operation, depending upon usage strength. strapping machine service. Normal analyses can aid establish certain requirements, guaranteeing peak performance and reducing downtime from equipment failing

Can I Execute Maintenance on My Own?

Yes, one can execute maintenance on their own, supplied they possess the essential skills and expertise. Getting in touch with the producer's standards is necessary to ensure appropriate treatments are followed and safety is preserved.What Signs Indicate I Required Immediate Service?

Indicators indicating the requirement for immediate service consist of uncommon noises, inconsistent strapping tension, regular error messages, noticeable endure elements, or unexpected see here shutdowns (strapping machine service). Attending to these problems promptly ensures functional efficiency and protects against more damageJust How Does Climate Affect Strapping Machine Performance?

Weather condition problems can greatly impact strapping machine performance. Extreme temperature levels, moisture, and dampness levels may create products to increase or agreement, influencing tension and seal integrity, causing prospective operational issues and decreased product packaging effectiveness.

What Is the Typical Expense of Regimen Service?

The ordinary cost of regular service for strapping machines normally ranges from $150 to $500, depending upon the machine's intricacy and the company's knowledge, guaranteeing peak efficiency and long life of the devices.Regular strapping machine service plays a necessary role in making sure efficient packaging operations. Routine service of strapping machines greatly boosts functional performance by guaranteeing that all elements work at their finest. While carrying out routine service on a strapping machine, it is crucial to monitor several vital components to secure peak efficiency and durability. By focusing on routine service, organizations can lessen downtime, prolong the machine's lifespan, and preserve regular packaging high quality. Consistent machine treatment greatly affects the durability and performance of strapping machines, as normal maintenance assists recognize possible issues before they intensify.

Report this wiki page